-

-

-

-

USA Lab 5L Single Jacketed Glass Reactor (Optional ETL, Explosion Proof & Pneumatic Mixers)

USA LabJR5Sale $3,739.00 - $4,850.00Retail -

USA Lab 20L Single Jacketed Glass Reactor w/ Ultrasonic Wand

USA LabJR20-ETL-ULTRASale $9,799.00Retail20L Ultrasonic Reactor System with Integrated Wand | USA Lab

Description

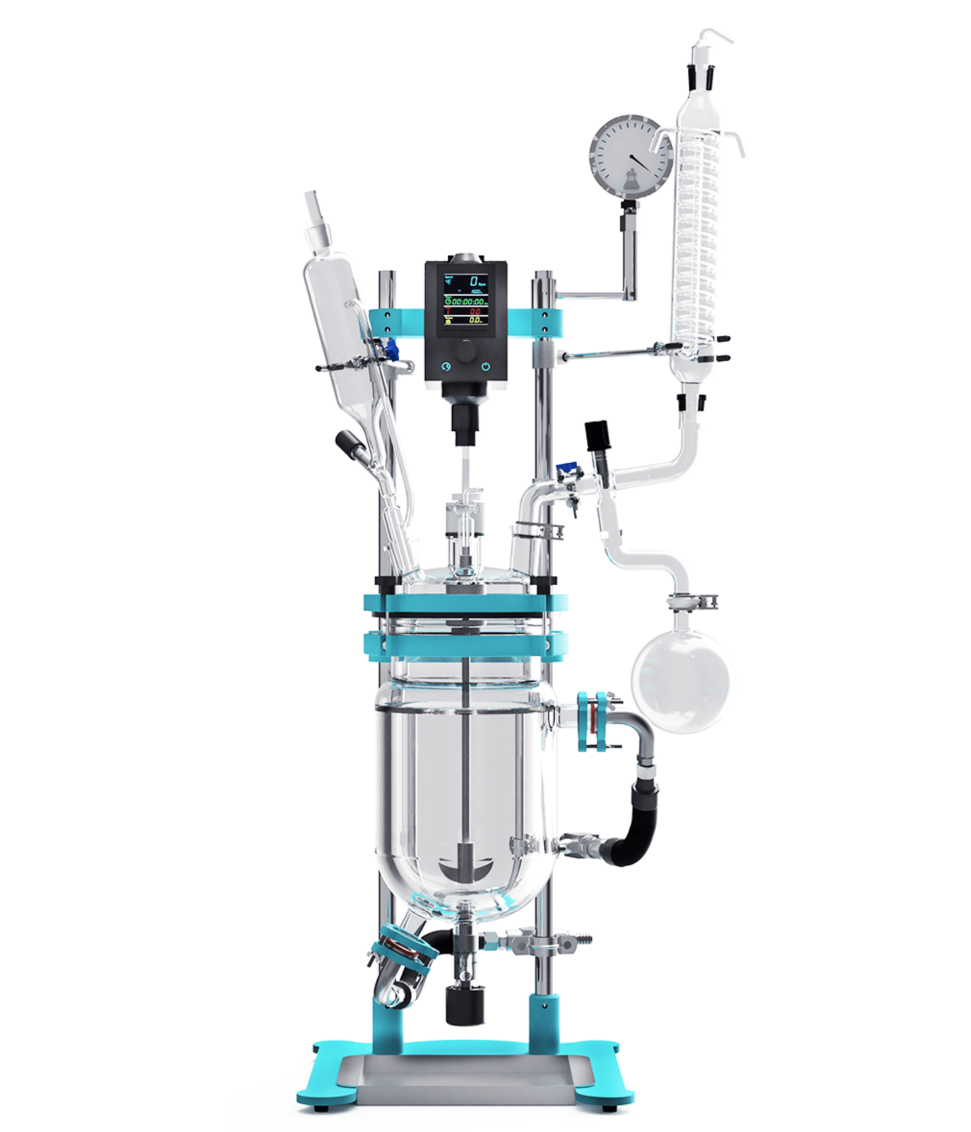

5L Benchtop Single Jacketed Glass Reactor | USA Lab

Our 5L Benchtop Jacketed Glass Reactor is engineered for precision, durability, and versatility in laboratory research and production. Constructed from premium borosilicate glass, this single-jacketed reactor provides exceptional chemical resistance and thermal stability, ensuring reliable performance across a wide range of processes.

Ideal for chemical synthesis, distillation, crystallization, extraction, and other batch reactions, this 5-liter glass reactor delivers consistent temperature control for both small-scale R&D and pilot laboratory applications. Its compact benchtop design makes it an excellent choice for labs seeking efficient mixing, heating, and cooling in a controlled environment.

Borosilicate Glass Single-Jacketed Design Compact Benchtop Size Adjustable Stirring System

Wide Temperature Range: Handles -80°C to 210°C (-112°F to 410°F) for maximum versatility.

Vacuum Capability: Achieves as low as 0.0033 Mpa (25 Torr / 25,000 Micron) for controlled reactions.

Variable Speed Control: Rotary stirring adjustable from 50–1500 RPM.

Why buy from USA Lab

Expert Support

Engineers & technicians on staff.

Engineers & technicians on staff.

Quality First

Tested and trusted products.

Tested and trusted products.

Fast Fulfillment

Nationwide 1-2 day shipping.

Nationwide 1-2 day shipping.

Warranty & Parts

US-based service & spares.

US-based service & spares.

Resources & Downloads

Why this reactor?

- Durable borosilicate glass — excellent chemical resistance and thermal stability for long-term lab use.

- Precise temperature control — single-jacketed design supports heating and cooling with circulating systems.

- Compact & versatile — ideal for R&D, universities, and small-scale process development.

- Reliable stirring system — adjustable-speed motor ensures consistent, efficient mixing.

- Easy integration — standard glass joints and NPT connections for seamless lab setup.

Talk to an expert

Get sizing help, SOP guidance, and integration tips for your line.

Technical Specifications

| Model | JRBT 1L | JRBT 2L | JRBT 5L |

|---|---|---|---|

| Vessel Capacity | 1L / 0.26Gal | 2L / 0.53 Gal | 5L / 1.32Gal |

| Material Flask Capacity | 500ml | 500ml | 500ml |

| Receiving Flask Capacity | 1000ml | 1000ml | 1000ml |

| Fluid Jacket Capacity | 250ml | 250ml | 800ml |

| Glass Material | GG-17 Borosilicate Glass | Thickness: 6.5mm ±0.5mm | GG-17 Borosilicate Glass | Thickness: 6.5mm ±0.5mm | GG-17 Borosilicate Glass | Thickness: 6.5mm ±0.5mm |

| Rotary Speed | 50-1500RPM | 50-1500RPM | 50-1500RPM |

| Glass Temperature Range | -80°C to 210°C / -112°F to 410°F | -80°C to 210°C / -112°F to 410°F | -80°C to 210°C / -112°F to 410°F |

| Power Requirements | 110-120V 60Hz 15A | 110-120V 60Hz 15A | 110-120V 60Hz 15A |

| Stirrer Wattage | 120W | 120W | 120W |

| Lowest Vacuum Level | 0.0033 Mpa | 25 Torr | 25,000 Micron | 0.0033 Mpa | 25 Torr | 25,000 Micron | 0.0033 Mpa | 25 Torr | 25,000 Micron |

| Condenser and Feed Valve Barbs | 10MM - 3/8" | 10MM - 3/8" | 10MM - 3/8" |

| Bottom Drain Port | 35MM - 1 3/8" | 35MM - 1 3/8" | 35MM - 1 3/8" |

| Receiving Flask Barb | 16MM - 5/8" | 16MM - 5/8" | 16MM - 5/8" |

| Jacket Pressure | Maximum 11.6 psi - Nominal 7.25 psi | Maximum 11.6 psi - Nominal 7.25 psi | Maximum 11.6 psi - Nominal 7.25 psi |

| Fluid Connection | 16MM - 5/8" barb or 1/2" NPT | 16MM - 5/8" barb or 1/2" NPT | 16MM - 5/8" barb or 1/2" NPT |

| External Dimensions LxWxH | 18 x 18 x 41" | 18 x 18 x 47" | 13 x 15 x 58" |

| Weight | 72 lbs | 75 lbs | 114 lbs |

Motor Specifications

| Model | JRBT -STIRRER |

|---|---|

| Max Stir capacity (H2O) [L] | 40 |

| Input Power [W] | 120 |

| Motor Output Power [W] | 100 |

| Voltage [VAC] | 100-240 |

| Frequency [Hz] | 50/60 |

| Power [W] | 130 |

| Speed, Time, Torque, Temp display | Digital Screen Display |

| Timing range | 0-99h59min |

| Rotary range [rpm] | 50-2200 |

| Speed accuracy [rpm] | ±1 |

| Max Torque [N.cm] | 60 |

| Overload Protection | Auto stop |

| Motor Protection | Auto stop |

| Max Viscosity [mPas] | 50000 |

| Drill Chuck | Import anti-corrosion and self-tension type |

| diameter range [mm] | 0.5-10 |

| protection class(DIN EN 60529) | IP42 |

| Environment Temp [oC] | May-40 |

| Related humidity [%] | 80 |

| RS485Interface | Yes |

| Probe | Yes |

| Power |

110V~60HZ |

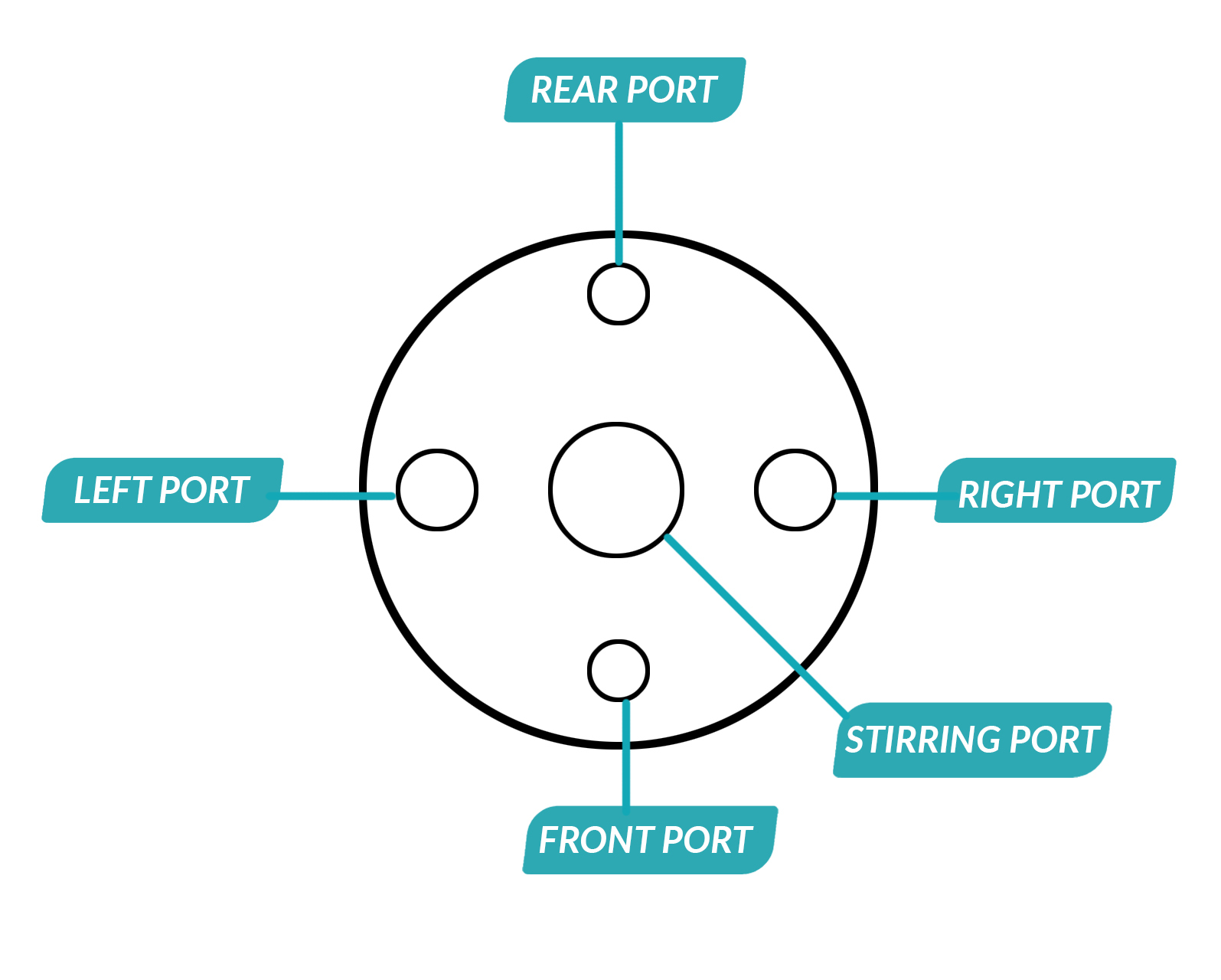

Lid Specifications

| Model | JRBT 1L | JRBT 2L | JRBT 5L |

|---|---|---|---|

| Left Port | 24/29 Joint | 24/29 Joint | 24/29 Joint |

| Right Port | S35 Ball Joint | S35 Ball Joint | S35 Ball Joint |

| Stirring Port | 50mm Flange Port | 50mm Flange Port | 50mm Flange Port |

| Front Port | 19/26 Joint | 19/26 Joint | 19/26 Joint |

| Rear Port | 19/26 Joint | 19/26 Joint | 19/26 Joint |

Popular Industries & Use Cases

Business Solutions & Procurement

Programs & Terms

Exclusive options for businesses and academics.

Documentation & Compliance

Keep purchasing streamlined and compliant.

Custom Solutions

Tailored tanks, skids, and integration help.

Talk to Sales

We’ll help spec the right system for your throughput.

FAQ

What types of applications is this 5L reactor best suited for?

This reactor is ideal for chemical synthesis, distillation, crystallization, extraction, and other batch reactions. Its compact size makes it especially well-suited for R&D labs, universities, and small-scale pilot projects.

What temperature range can the reactor handle?

The single-jacketed glass vessel supports a wide operating range of -80°C to 210°C (-112°F to 410°F), allowing both cryogenic and high-temperature reactions.

Can this reactor operate under vacuum conditions?

Yes. It is capable of reaching as low as 0.0033 Mpa (25 Torr / 25,000 Micron), making it suitable for controlled vacuum-assisted processes.

How is temperature control managed with this system?

The jacket is designed to connect to a circulating heater or chiller, enabling precise control of reaction temperatures for reliable, repeatable results.

Important Shipping Notice!

DISCLAIMER:

All items are carefully packaged to ensure safe delivery. In the rare event that your item arrives damaged, please notify us within 3 days of receipt. We will promptly provide a replacement or issue a refund.

Please note that any damage occurring after delivery is not covered under warranty. We appreciate your understanding and your trust in our products.

×

Email Sales & Support

We usually reply same business day.

×

Technical Support

Share details and our techs will follow up.

×

Request a Quote

Tell us what you need and we’ll respond quickly.

Product Documents

Download COAs, SDS, Manuals, Specs, and Drawings for this product.

Loading documents…