How Fractional Distillation Process Works

Posted by USA Lab Equipment on Nov 11th 2020

Fractional distillation is a common procedure that is highly effective at separating various components in a substance, enabling the creation of numerous products. Since its inception in the 20th century, fractional distillation has become a prominent process in many industries, from small laboratories to large industrial plants. To learn more about this powerful distillation process and its many applications, consult this complete guide to the fractional distillation process.

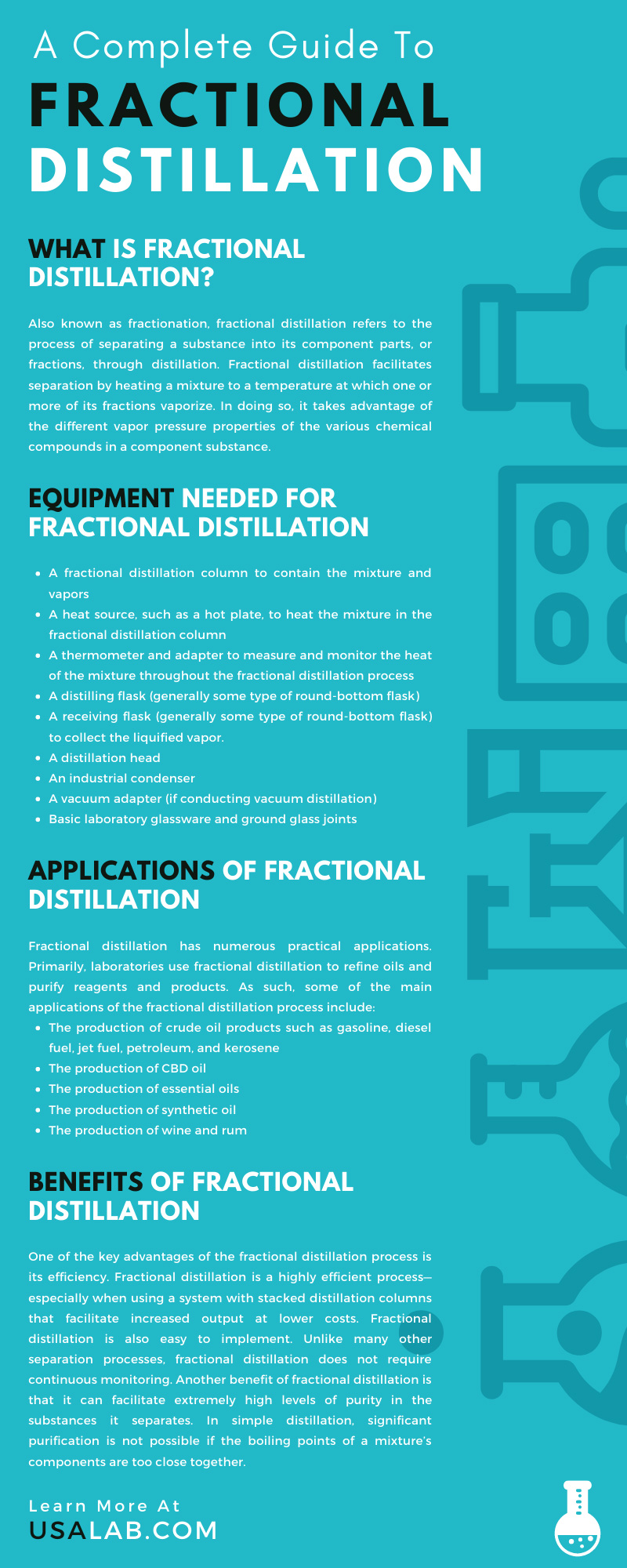

What Is Fractional Distillation?

Also known as fractionation, fractional distillation refers to the process of separating a substance into its component parts, or fractions, through distillation. The fractional distillation process facilitates separation by heating a mixture to a temperature at which one or more of its fractions vaporize. In doing so, it takes advantage of the different vapor pressure properties of the various chemical compounds in a component substance. This technique allows the production of highly purified products with less effort and shorter turnaround times than would be possible through repeated simple distillations.

How Fractional Distillation Works

The basic steps of the fractional distillation process involves the following steps:

- Place a mixture in the fractional distillation column, and add heat until the temperature reaches the boiling point of the chemical compound within the substance with the lowest boiling point.

- Once it has reached that temperature, the component with the lowest boiling point will vaporize, leaving some of the molecules of the other substances in the mixture. Then, the vaporized component will rise through the fractional distillation column. The higher it rises in the column, the purer the vapor will become as heavier molecules will fall away and condense back to their liquid state.

- Throughout the process, vapor in the column will consistently rise as liquid falls. The fractional columns include various areas that have similar quantities of molecules of each type of substance in the mixture, commonly known as stages. To properly separate the components of the mixture, the fractional column you use must be able to contain the minimum number of required stages. The percentage of separation that the column can contain will largely depend on its height.

- Once vapor reaches the top of the fractional distillation column, it will collect in a big chiller known as an industrial condenser. The industrial condenser will serve to cool the vapor until it condenses back into its original, liquid state. Then the liquified vapor will be piped into a tank or put into storage. You can also pull and condense mixtures at various stages as the vaporous substances rise. In many cases, a fractional distillation system can achieve numerous products at several different points inside of the distillation column.

- The remaining substances in the column will continue undergoing the distillation process until it achieves the desired purity level of the mixture. In many cases, the solution will recirculate throughout the system numerous times to ensure optimal separation.

Equipment Needed for Fractional Distillation

- A fractional distillation column to contain the mixture and vapors

- A heat source, such as a hot plate, to heat the mixture in the fractional distillation column

- A thermometer and adapter to measure and monitor the heat of the mixture throughout the fractional distillation process

- A distilling flask (generally some type of round-bottom flask)

- A receiving flask (generally some type of round-bottom flask) to collect the liquified vapor.

- A distillation head

- An industrial condenser

- A vacuum adapter (if conducting vacuum distillation)

- Basic laboratory glassware and ground glass joints

To carry out this process, a variety of fractional distillation apparatus is necessary. Essential types of laboratory equipment that are needed to complete the process of fractional distillation include:

Applications of Fractional Distillation

Fractional distillation has numerous practical applications. Primarily, laboratories use fractional distillation to refine oils and purify reagents and products. As such, some of the main applications of the fractional distillation process include:

- The production of crude oil products such as gasoline, diesel fuel, jet fuel, petroleum, and kerosene

- The production of CBD oil

- The production of essential oils

- The production of synthetic oil

- The production of wine and rum

Benefits of Fractional Distillation

Now that we have reviewed what fractional distillation is, its primary applications, and fractional distillation apparatus, we’ll discuss why one may choose fractional distillation over other separation processes. Below, we have listed some of the main benefits of the fractional distillation process.

Efficiency

One of the key advantages of the fractional distillation process is its efficiency. Fractional distillation is a highly efficient process—especially when using a system with stacked distillation columns that facilitate increased output at lower costs. In a single distillation, fractional distillation can isolate and recover numerous components, which is not possible with simple distillation.

Ease of Implementation

Fractional distillation is also easy to implement. Unlike many other separation processes, fractional distillation does not require continuous monitoring. Once you’ve set up the fractional distillation system properly, you can leave it to commence the process on its own. While you should check the system periodically to ensure that it is functioning correctly, continuous supervision is not necessary. Modern fractional distillation systems are especially easy to implement as they are often automated using microprocessors.

High Purity Level

Another benefit of the fractional distillation process is that it can facilitate extremely high levels of purity in the substances it separates. In simple distillation, significant purification is not possible if the boiling points of a mixture’s components are too close together. Fractional distillation, however, takes advantage of the varying vapor pressure properties of the chemical compounds in a mixture to achieve optimum purification.

For the past decade, USA Lab Equipment has supplied top-quality new and used laboratory equipment to customers all across the country. During that time, we have remained committed to our goal of providing our customers with both impeccable products and exceptional customer service. At USA Lab Equipment, we want you to have the best possible experience buying lab equipment. From recirculating chillers to basic glassware, you can find the essential equipment, including fractional distillation apparatus, that your laboratory operations require at our warehouse or online. To learn more about our competitively priced products and equipment, contact us today.