An Overview of Rotary Evaporation

Jan 16th 2020

Present in many labs, the rotary evaporator is a commonly used piece of equipment that acts as a solvent remover. Using a rotary evaporator is one of the fastest, most-efficient, and environmentally friendly ways of removing a volatile solvent from a non-volatile sample. To gain a better understanding of this useful procedure, consult this comprehensive overview of rotary evaporation.

What is rotary evaporation?

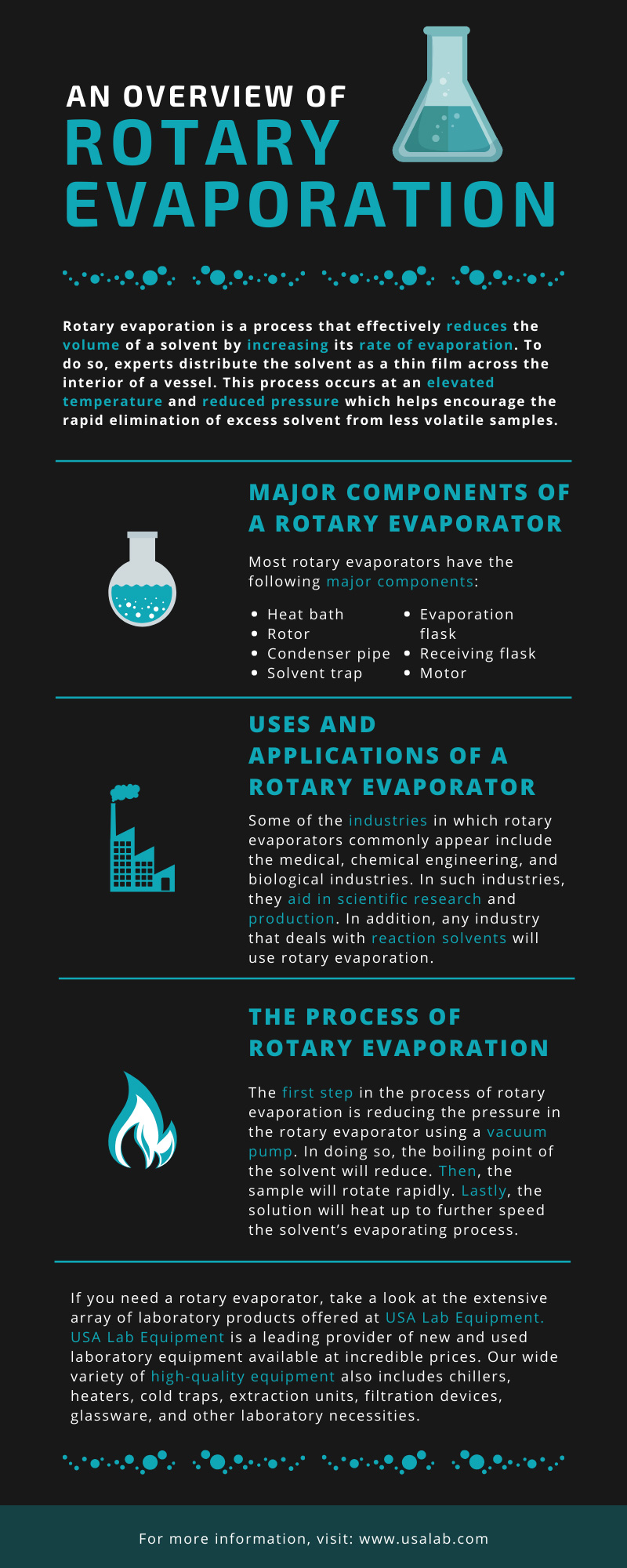

Rotary evaporation is a process that effectively reduces the volume of a solvent by increasing its rate of evaporation. To do so, experts distribute the solvent as a thin film across the interior of a vessel. This process occurs at an elevated temperature and reduced pressure which helps encourage the rapid elimination of excess solvent from less volatile samples.

Major components of a rotary evaporator

Most rotary evaporators have the following major components:

- Heat bath

- Rotor

- Condenser pipe

- Solvent trap

- Evaporation flask

- Receiving flask

- Motor

Uses and applications of a rotary evaporator

A wide variety of industries uses rotary evaporators. Some of the industries in which rotary evaporators commonly appear include the medical, chemical engineering, and biological industries. In such industries, they aid in scientific research and production. In addition, any industry that deals with reaction solvents will use rotary evaporation.

Recently, rotary evaporator applications have spread to additional industries such as the cooking and hemp industry. In the cooking industry, rotary evaporation assists in the process of molecular cooling—a subdiscipline of food science that investigates the chemical and physical transformations that occur during the cooking process. In the hemp industry, rotary evaporation is extremely effective for efficiently isolating the extracts and components of the hemp plant. As such, it is beneficial for producing high-quality hemp-derived products such as CBD oil.

The process of rotary evaporation

The first step in the process of rotary evaporation is reducing the pressure in the rotary evaporator using a vacuum pump. In doing so, the boiling point of the solvent will reduce. Then, the sample will rotate rapidly. As a result of the rapid rotation, the surface area of the sample will increase, which will facilitate a quicker evaporation process of the solvent. Lastly, the solution will heat up to further speed the solvent’s evaporating process. By the end, the rotary evaporation process should completely eliminate the solvent from the sample.

How to operate a rotary evaporator

- Before operating the rotary evaporator, you must properly set it up. To do so, pour the sample into a round bottom flask. This flask should then connect to the evaporator’s bump trap using a Keck clip. Then, fill the rotary evaporator’s cold traps with dry ice. After doing so, attach the flask and bump trap to the adapter portion of the rotary evaporator and secure it with a Keck clip. This feature will prevent your solution from entering the main part of the rotary evaporator.

- The last preparatory step is to lower the flask into the water bath using the joystick knob on the rotary evaporator. You should do this step once condensation begins to form on the flask’s exterior. Be sure to partially submerge the flask—approximately half-way—into the heat bath. It shouldn’t be so low that the joint with the Keck clip touches the water.

- Now that everything is set up, activate the rotor. The speed of the rotor will depend on the volume of your sample. The rotor should spin quick enough that it creates an even coating of the sample on the surface of the flask.

- Next, activate the vacuum pump. Slowly increase the vacuum to the proper strength. The sample will likely begin to boil. This should not cause concern unless the bubbles begin to reach the neck of the flask. If this occurs, re-pressurize the system by opening the stopcock fully. After the boiling has ceased, fully close the stopcock.

- Close the stopcock on the evaporator. To do so, turn the stopcock perpendicular to the bleed valve.

- Then, turn on the heat for the water bath.

- Monitor the rotary evaporator for a few minutes. If there is no sign of bumping, it should be safe to leave the rotary evaporator unattended. However, you should continue to check in throughout the process periodically to ensure that nothing goes wrong.

- Upon eliminating all the solvent, turn off the vacuum.

- Then, turn the flask to atmospheric pressure and stop the rotation.

- Lastly, raise the flask from the bath and remove the flask from the adapter. If it did not completely remove the solvent, add it back into the same flask and repeat the procedure.

How to stop the rotary evaporation process

After starting the process of rotary evaporation, there may be some instances in which you seek to stop the procedure. In this case, it is important to follow specific steps to prevent broken glassware, injury, ruining the sample, damaging the equipment, and other undesirable outcomes. The steps to halting the process of rotary evaporation are as follows:

- Remove the flask from the heat bath using the joystick

- Open the stopcock fully

- Turn off the rotor

- Turn off the vacuum source

- Lift the flask from the water bath

- Remove the flask from the adapter portion of the rotary evaporator

- Turn the evaporator off completely

If you need a rotary evaporator, take a look at the extensive array of laboratory products offered at USA Lab Equipment. USA Lab Equipment is a leading provider of new and used laboratory equipment available at incredible prices. We offer 2-, 5-, 10-, 20-, and 50-liter rotary evaporators. Our wide variety of high-quality equipment also includes chillers, heaters, cold traps, extraction units, filtration devices, glassware, and other laboratory necessities.

In addition to sourcing our equipment from trusted third-party brands, we manufacture much of our equipment in-house. With over 1,000 items stocked in our warehouse, you are sure to find the equipment that you’re looking for right here at USA Lab Equipment. For more information regarding our products, contact us today.